Introduction

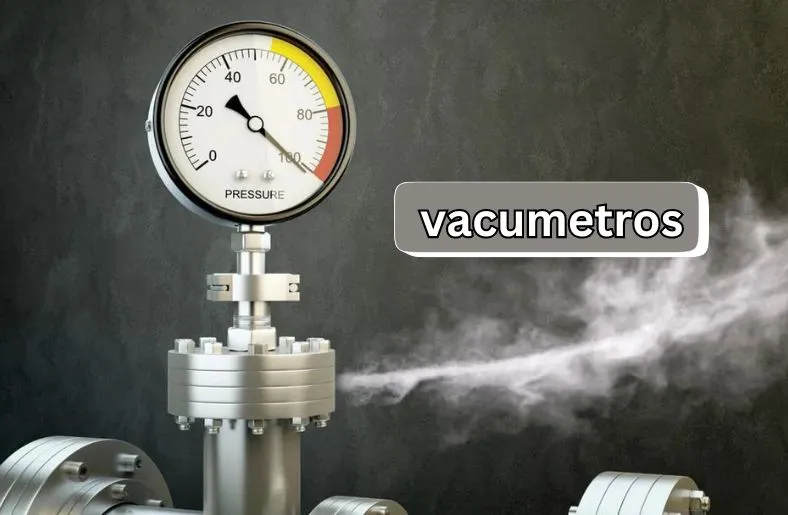

Vacumetros, also known as vacuum gauges, are crucial tools for measuring pressure in vacuum systems. They help ensure that various processes run smoothly by keeping the pressure at the right level. For example, in a factory or a science lab, having the correct vacuum pressure is vital for the equipment to work correctly.

In this blog post, we will explore what vacumetros are and why they are so important. We will look at the different types of vacumetros available and how they are used in different industries. Understanding these tools can help you see why accurate pressure measurement is so important for many processes. Whether you are working in manufacturing, science, or even space exploration, vacumetros play a key role in keeping things running efficiently. So, let’s dive into the world of vacumetros and discover their essential functions.

What Are Vacumetros?

Vacumetros, also called vacuum gauges, are devices that measure pressure in a vacuum system. They are essential for checking how much air or gas is removed from a sealed space. These tools help ensure that the right amount of vacuum is maintained for various processes.

There are different types of vacumetros, each designed for specific needs. Mechanical vacumetros use physical parts to measure pressure. For example, Bourdon tube gauges and diaphragm gauges fall into this category. They are simple and reliable for many tasks.

Electronic vacumetros offer more advanced features. They use sensors and electronic components to provide precise measurements. Common types include thermocouple gauges and ionization gauges. These are used when very accurate pressure readings are needed.

Vacumetros are important in many fields. In science labs, they help control experiments. In factories, they ensure equipment runs correctly. Even in space exploration, vacumetros play a role in testing spacecraft. Understanding how vacumetros work can help you appreciate their value in keeping systems functioning smoothly.

Types of Vacumetros

Vacumetros come in various types, each suited for different pressure ranges and applications. Understanding these types helps in choosing the right tool for your needs.

Mechanical Vacumetros

Mechanical vacumetros are the simplest and most durable. They use physical parts to measure pressure.

- Bourdon Tube Gauges: These have a coiled tube that straightens when pressure changes. They are good for medium vacuum ranges and are often used in industrial settings.

- Diaphragm Gauges: These have a flexible diaphragm that bends with pressure changes. They work well for lower pressure measurements and are used in many laboratory applications.

- Capsule Gauges: These contain a capsule that expands or contracts with pressure changes. They are used for low vacuum levels and are known for their simplicity.

Electronic Vacumetros

Electronic vacumetros provide more accurate and detailed measurements. They use electronic components and sensors.

- Thermocouple Gauges: These measure pressure by detecting changes in heat conduction. They are suitable for low to medium vacuum ranges and are often used in scientific research.

- Ionization Gauges: These measure pressure by ionizing the gas and measuring the resulting current. They are ideal for ultra-high vacuum levels and are commonly used in advanced scientific applications.

- Capacitance Manometers: These measure changes in capacitance due to pressure variations. They offer precise readings for both low and high vacuum ranges and are used in various industrial and research applications.

Choosing the Right Vacumetro

Selecting the appropriate vacumetro depends on several factors. First, consider the pressure range you need to measure. Mechanical vacumetros are typically simpler, while electronic ones offer more precision. Next, think about the environment where the vacumetro will be used. Mechanical gauges are robust, while electronic gauges may need more careful handling. Finally, ensure that the vacumetro meets the accuracy requirements of your specific application.

Applications of Vacumetros

Vacumetros are used in many different fields to measure and control vacuum pressure. Their role is crucial in ensuring that systems work correctly and efficiently.

Industrial Processes

In factories and manufacturing plants, vacumetros help control vacuum levels in equipment like pumps and coating machines. Accurate measurements are vital for product quality and process control.

Scientific Research

Researchers use vacumetros in laboratories for experiments that need precise vacuum conditions. They are used in vacuum chambers, particle accelerators, and spectroscopy. These measurements ensure reliable and accurate results in scientific studies.

Medical and Pharmaceutical Fields

Vacumetros are important in medical devices and pharmaceutical processes. For example, they are used in vacuum-assisted wound closures and equipment sterilization. In pharmaceuticals, they help during freeze-drying and vacuum distillation, maintaining the right conditions for making medicines.

Automotive and Aerospace Industries

In the automotive industry, vacumetros monitor vacuum systems in engines and braking systems. They are also used in testing vehicle components. In aerospace, they simulate outer space conditions for testing spacecraft parts.

Food Packaging

Vacumetros are used in the food industry to monitor vacuum levels during packaging. Vacuum packing extends the shelf life of food by removing air, which helps prevent spoilage. Accurate vacuum measurements are crucial to ensure that the food remains fresh and safe.

Vacuum Metallurgy

In metallurgy, metals are melted and cast in a vacuum to avoid contamination from air. Vacumetros ensure the correct vacuum levels are maintained, resulting in high-quality metals and alloys.

Space Simulation

Vacumetros are used to create and maintain high-vacuum environments in space simulation chambers. This helps test spacecraft and materials under conditions similar to outer space.

In all these applications, vacumetros play a key role in ensuring the accuracy and effectiveness of processes. They help maintain the right conditions, contributing to the success and safety of various operations.

Choosing the Right Vacumetro

Selecting the right vacumetro is essential for accurate pressure measurements. Here are key factors to consider:

- Vacuum Range

First, determine the vacuum range you need. Different vacumetros measure various pressure levels. Choose one that fits your specific needs, whether it’s low, medium, or ultra-high vacuum. - Accuracy and Precision

Next, think about how precise your measurements need to be. Some applications require high accuracy, while others can use less precise gauges. Electronic vacumetros usually offer better accuracy than mechanical ones. - Compatibility

Ensure the vacumetro matches your system. Check connection types, materials, and operating conditions. The gauge must be able to work well with your equipment and environment. - Cost and Maintenance

Consider your budget and maintenance needs. Mechanical vacumetros are often less expensive and simpler to maintain. However, electronic vacumetros might offer advanced features but can be costlier and need more upkeep. - Environmental Factors

Think about where the vacumetro will be used. If it’s in a harsh environment, select a model that’s durable and resistant to contaminants or extreme temperatures. - Ease of Use

Choose a vacumetro that is user-friendly. Easy-to-read displays and straightforward controls can simplify operation and reduce errors.

By considering these factors, you can select a vacumetro that fits your needs perfectly. The right choice ensures accurate measurements and helps maintain the efficiency of your system.

Maintenance and Calibration

Proper maintenance and calibration are vital for keeping vacumetros accurate and reliable. Regular checks help ensure they work correctly over time.

- Routine Calibration

Start with routine calibration. This process aligns your vacumetro with standard measurements. Regular calibration prevents drift and maintains accuracy. - Cleaning

Next, clean the vacumetro regularly. Dust, dirt, and other contaminants can affect its performance. Follow the manufacturer’s guidelines for cleaning. - Inspection

Inspect your vacumetro for any signs of wear or damage. Check connections, seals, and the display for any issues. Address any problems immediately to prevent further damage. - Functional Testing

Perform functional tests to ensure your vacumetro operates correctly. Test it under different conditions to check its response and accuracy. - Software Updates

If you have a digital vacumetro, keep its software updated. Manufacturers may release updates that improve performance or fix bugs. - Professional Servicing

Consider professional servicing if your vacumetro has complex issues. Technicians can perform in-depth repairs and adjustments that are not possible with routine maintenance.

By following these steps, you can extend the life of your vacumetro and ensure it remains accurate. Regular care helps avoid costly errors and maintains the efficiency of your system.

Future Trends in Vacumetro Technology

Vacumetro technology is evolving rapidly, bringing exciting advancements. First, digital vacumetros are becoming more common. They offer higher accuracy and easy readability compared to analog models.

Next, wireless connectivity is a growing trend. With this feature, users can monitor vacumetros remotely. This makes it easier to track vacuum levels from a distance and improve efficiency.

Another trend is the use of advanced materials. These new materials make vacumetros more durable and resistant to harsh conditions. This enhances their performance in tough environments.

Lastly, automation is on the rise. Automated vacumetros can adjust settings based on real-time measurements. This improves precision and reduces the need for manual intervention.

Conclusion

Vacumetros are vital tools for accurately measuring and maintaining vacuum pressure across various industries. From ensuring quality in manufacturing to supporting precise scientific research, their role cannot be overstated. Understanding the different types and applications of vacumetros helps in choosing the right tool for specific needs. As technology advances, new features like digital displays and wireless connectivity are enhancing their functionality. Proper maintenance and calibration are crucial for ensuring reliable performance. By staying informed about these developments, you can ensure optimal operation and efficiency in any system that relies on precise vacuum measurements.